FIRECEL SR114H

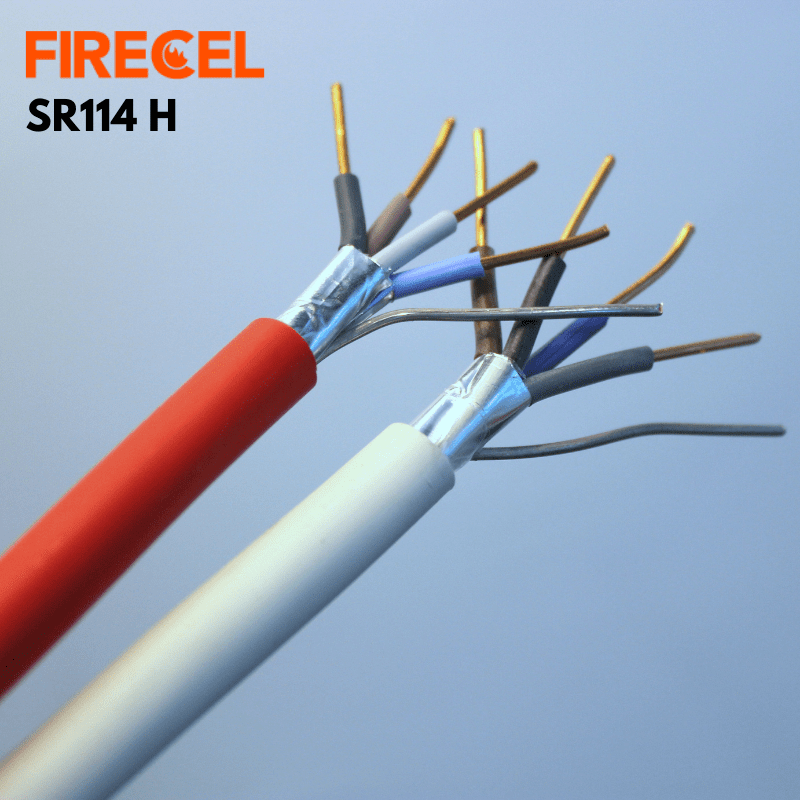

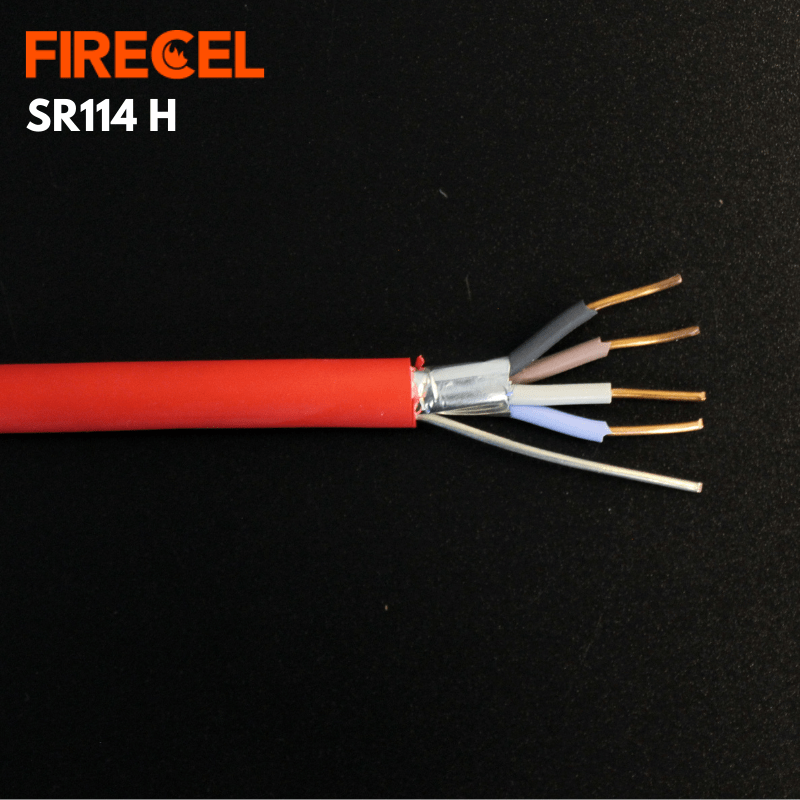

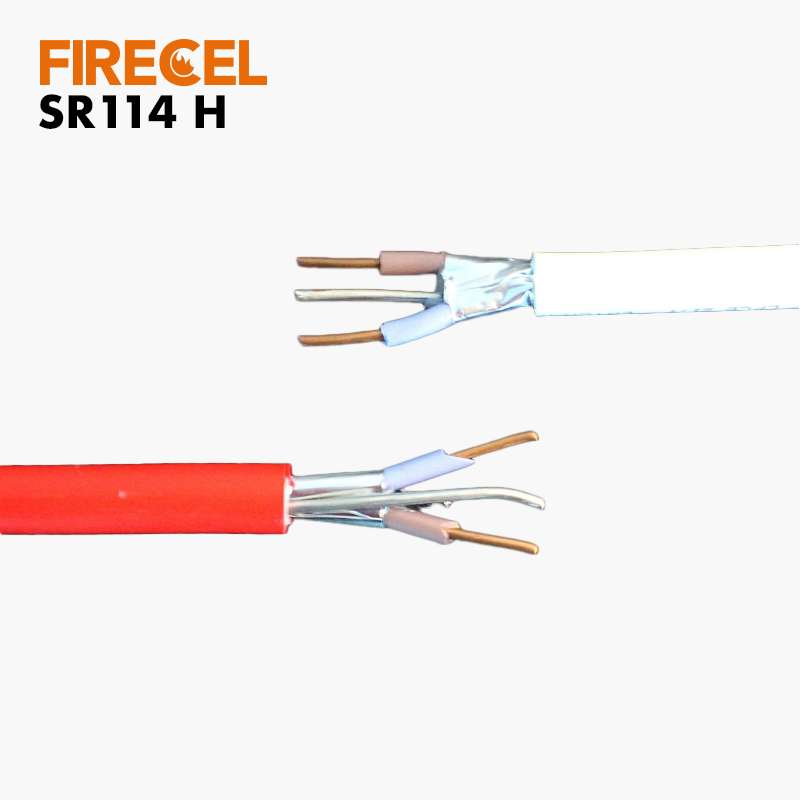

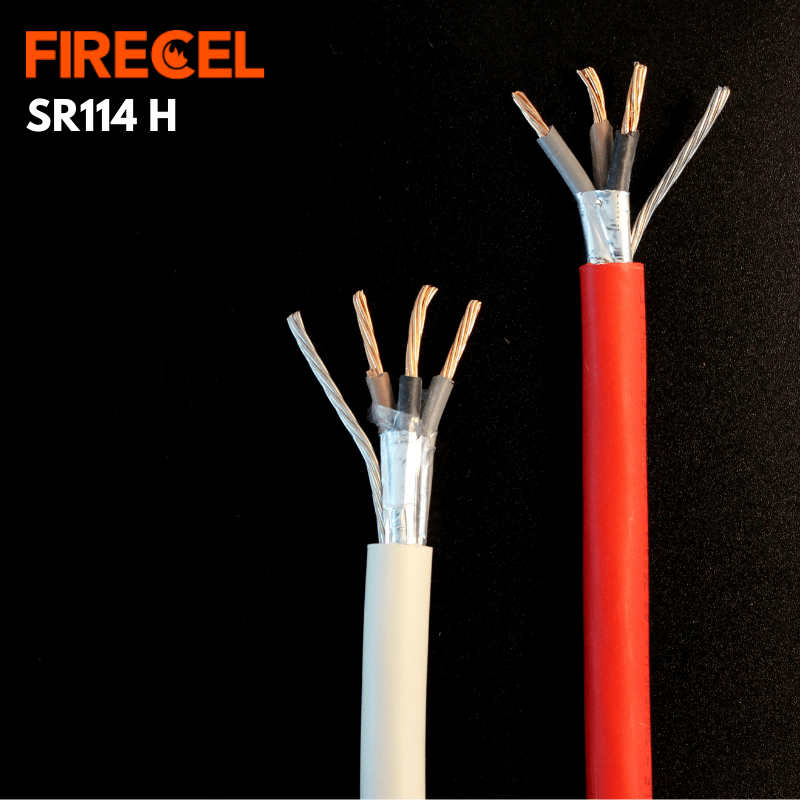

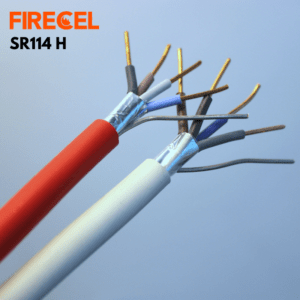

Silicone Insulation, Overall Screen, Solid and Stranded Conductor

Operating Temperature

-40°C to +90°C

-40°C to +90°C

Minimum Bending Radius

6 times the outer diameter.

6 times the outer diameter.

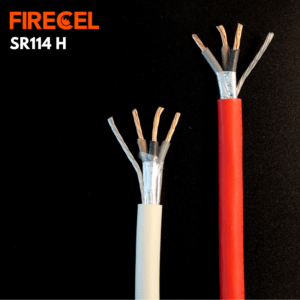

Colour Code up to 4 Cores to HD 308

| 2 cores | blue – brown |

| 3 cores | brown – black – grey |

| 4 cores | blue – brown – black – grey |

| 7 cores | centre: brown 1st layer: brown – black – 4 cores white |

| 12 cores | centre: brown – black – white 1st layer: brown – black – 7 cores white |

| 19 cores | centre: brown 1st layer: brown – black – 4 cores white 2nd layer: brown – black – 10 cores white |

(on request the cores can be one colour only, identified by printed numbers)

Applicable Standards

| Basic design | BS 7629-1 |

| Fire resistant | BS 6387 (cat. C-W-Z) EN 50200 (class PH120) BS 8434-2 (120 min) |

| Flame retardant | EN 60332-1-2 |

| Acid gas emission | EN 50267-2-1 |

| Smoke density | EN 61034-2 |

Cable Construction

Conductors – Plain annealed copper wire, solid class 1 or stranded class 2 according to EN 60228

Insulation – High performance fire resistant cables silicone rubber type EI2 to BS EN 503

Cabling – Insulated cores are cabled together.

Overall screen – Aluminium/Polyester tape

Circuit protective conductor – Uninsulated tinned copper conductor of the same section and class as the insulated conductors in the 2-, 3- and 4-core cables. Drain wire of 0.5 mm2 tinned copper conductor is provided in cables with more than 4 conductors.

Outer sheath – LSZH thermoplastic material type LTS3 to BS 7655-6.1

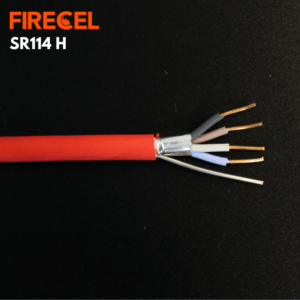

Colour – Red or White (other colours on request)