Misterlight provides a wide range of Instrumentation Cables designed and manufactured in accordance with BS, IEC, NF, DIN and ANSI standards.

Instrumentation cables are specifically designed to transmit electrical signals from one location to another, and they can be either single-pair or multi-pair cables. These cables play a crucial role in conveying signals generated by different transducers to panels, electronic or PID controllers, and field instruments. They find extensive use in various applications across industrial process manufacturing plants for control purposes, as well as for communication, data transmission (both analog and digital), and voice transmission signals. Industries such as Oil & Gas, Petro-Chemicals, Off-Shore Oil Rigs, Cement Factories, Refineries, petrochemical platforms, Steelworks, and Desalinating plants rely on these cables for their operations.

There are three types of instrumentation cables, which are classified according to the signal level they transmit.

- Instrumentation High-level signals refer to cables that transmit signals ranging from 1V to 50V.

- Instrumentation Low-level signals refer to cables that transmit signals below 6V.

- Instrumentation Power Supply refers to cables that transmit signals above 50V.

Standards for Instrumentation Cables

Our range of instrumentation cables, featuring flexible copper conductors, is in accordance with various British and International Standards. These include British standard BS5308 for instrumentation cables, French standard NF M87-202, European standard BS EN 50288-7, and US UL standard PLTC cables.

We adhere to several key national standards when supplying our instrumentation cables, which include:

- British standards: BS5308 Part 1 and Part 2 cables

- British/European standards: BS EN 50288-7 cables

- French standards: NF M87-202 cables

- North American standards: UL 13, UL 2250, UL 1277 cables

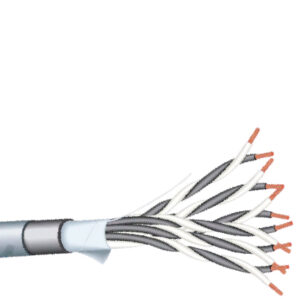

The above mentioned includes a variety of types of cables used for instrumentation, such as collectively screened (CAM) and individually screened and collectively screened (ICAM) cables. These cables are insulated with materials like Polyethylene (PE), cross-linked Polyethylene (XLPE), Polyvinyl Chloride (PVC), or Silicone (Si). Typically, they are also equipped with a PVC outer sheath or low smoke zero halogen (LSZH) sheathing to prevent the release of smoke and acid gas during a fire. Additionally, our cables, including BS5308 Part 2 instrumentation cables, can be armored with steel wire or steel tape for added protection against mechanical stresses.

What type of cable is used in instrumentation?

In order to transmit electrical signals between different points, a variety of cables are utilized in instrumentation.

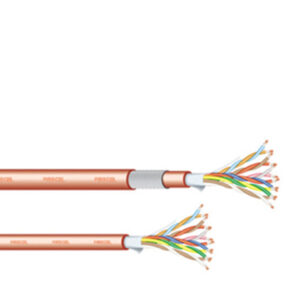

Shielded Twisted Pair (STP) Cable

- In general, the Shielded Twisted Pair (STP) cable is commonly referred to as the Ethernet cable.

- This type of cable, known as Shielded Twisted Pair, is primarily used in business installations and consists of a special copper telephone cabling.

- It features a standard twisted pair of telephone wires combined with an external shield that serves as a ground.

- Shielded Twisted Pair cables are particularly suitable for areas or locations with a high risk of interference.

- By incorporating this type of cable, it becomes possible to extend the distance covered by the network connection.

- To reduce electromagnetic interference, these Shielded Twisted Pair cables include four pairs of signal-carrying wires that act as a conducting shield.

- STP cables are classified into various categories such as CAT-5, CAT-6, CAT-6a, and CAT-7.

Unshielded Twisted Pair (UTP) Cable

- The UTP copper cable has a resistance of 100 ohms.

- It consists of approximately 2 to 1800 unshielded twisted pairs enclosed by an outer jacket.

- There is no metallic shield present in these cables.

- This cable does not offer any protection against electrical interference.

- The twisting of the pairs helps to enhance immunity against electrical noise and electromagnetic interference.

- UTP cables are classified as CAT-5e and CAT-6.

- For horizontal cables, there are four (4) pairs, while for backbone cables, the number of pairs increases to 25.

- Both horizontal and backbone UTP cables have a copper conductor size of AWG-22 or AWG-24, with AWG-24 being the most common size used.

- CAT-6 is a higher-performance cable that utilizes AWG-24 copper wire.

- Initially developed for voice applications to transmit analog signals, UTP cables are now widely used in Telecommunication, Computer, and Networking sectors as Ethernet cables.

- These tough Unshielded Twisted Pair (UTP) cables are not susceptible to damage from electrical noise or electromagnetic interference.

- UTP cables are categorized into Higher-category UTP, known as Data grade UTP cables, and Lower-category UTP, known as Voice-grade UTP cables.

Coaxial Cable:

- The coaxial cable is made up of two conductors, with an outer braided cylinder and an inner stranded conductor.

- A solid dielectric material is situated between the inner conductor and the outer cylinder.

- The term “coaxial” means that the inner conductor and outer cylinder shield share a common axis.

- To provide overall protection, the outer cylinder is covered by an insulating jacket.

- Coaxial cables are used as feed lines to connect radio transmitters and receivers to their antennas.

- In an ideal coaxial cable, the electromagnetic field that carries a signal exists in the space between the inner conductor and outer cylinder.

- Coaxial cables are flexible transmission mediums designed to transmit large amounts of data.

- These cables can be used in point-to-point or multipoint configurations.

- They are commonly found in bus network topology, and occasionally in a ring topology.

- Coaxial cabling is utilized for both analog signaling and digital signaling referred to as broadband.

What is the difference between control cables and instrumentation cables?

Control cables and instrumentation cables are both used in electrical systems, but there are some key differences between the two.

Control cables are designed to transmit control signals or power between devices in a system. They are typically used for connecting and controlling motors, valves, switches, and other electrical equipment. Control cables often have multiple conductors and may also include shielding to protect against electromagnetic interference.

On the other hand, instrumentation cables are specifically designed for transmitting low-voltage signals from sensors or measuring devices to control systems or monitoring equipment. These cables are used in applications where precise measurements and signal accuracy are critical, such as in industrial process control or scientific research. Instrumentation cables typically have twisted pairs of conductors for better signal integrity and may also have shielding to minimize interference.

In summary, while both control cables and instrumentation cables are used in electrical systems, control cables are primarily used for transmitting power and control signals between devices, while instrumentation cables are used for transmitting low-voltage signals with high accuracy and reliability.

What Makes Misterlight the Best Choice for Your Reliable Instrumentation Cable Supplier in UAE?

Choosing Misterlight as your instrumentation cable supplier in UAE comes with several benefits. We offer a wide range of high-quality cables that are reliable and durable, ensuring long-term performance. These cables are sourced from renowned international brands and are designed to meet various industry standards and specifications, making them suitable for different applications. Moreover, we have an experienced team of professionals who can provide technical assistance and support to ensure you choose the right cable for your specific needs. With our competitive pricing and excellent customer service, choosing us as your instrumentation cable supplier is a smart choice for any business looking for reliable and efficient solutions.